Golf balls are made through a multi-stage process that's far more complex than most golfers realize. It starts with mixing synthetic rubber compounds under precise heat and pressure to form the core, which is then vulcanized and ground to exact specifications. Manufacturers add mantle layers for performance tuning, then injection-mold the cover while simultaneously creating those aerodynamic dimples. Ultimately, robotic systems apply paint and clear coats before rigorous quality testing, and each step dramatically affects how the ball performs off your clubface.

Every golf ball you've ever striped down the fairway started its life as a sticky mess of synthetic rubber and chemicals churning inside a two-story industrial mixer.

Here's what manufacturers don't tell you: that core's performance is locked in before molding ever begins. Polybutadiene rubber gets blended with proprietary oils, polyolefins, and peroxide curing agents in ratios that remain closely guarded secrets. The shearing action during mixing distributes these additives evenly while generating heat that kickstarts chemical reactions. These high-energy materials are specifically chosen because they maximize the initial velocity when the clubface makes contact.

You'd think all premium balls start equal, but they don't. Batch consistency depends entirely on precise control of mixing time, temperature, and speed. Every batch gets weighed, tested, and analyzed before moving forward. Variations here mean differences in compression, feel, and the energy transfer that determines your distance off the tee. Once the compound passes inspection, it moves to a shaping process where heat and pressure cure the rubber into a perfect sphere. Once approved, these mixed materials are fed through chilled rollers that process the compound into a form ready for the next stage of production.

That sticky rubber mixture from the mixer doesn't magically change into a perfect sphere; it requires brutal force and precise heat to get there.

After aging, workers form the compound into uniform slugs, dense, cake-batter-like chunks ready for conversion. Steel molds clamp down with over a ton of pressure while temperatures hit 160°C. You're looking at 13 minutes per core to achieve complete vulcanization.

Here's where precision matters: those molded cores aren't finished. Grinding machines shave each sphere to exactly 1.5 inches in diameter, removing imperfections and achieving tight tolerances. Some cores get re-ground multiple times.

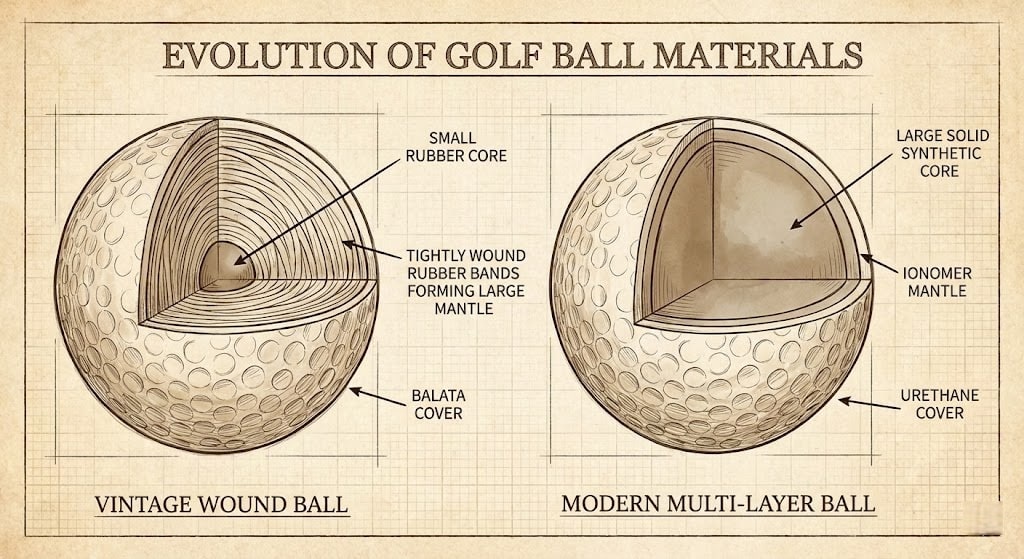

Every core faces X-rays and measurements to catch density irregularities. Mechanized milling strips away flash, that excess rubber squeezed out during molding. This obsessive quality control guarantees the consistent compression characteristics you feel at impact. Leading manufacturers like Titleist produce their premium Pro V1 and Pro V1x balls at dedicated facilities in Massachusetts, where rigorous standards ensure every core meets exact specifications. The core functions as the engine of the golf ball, making this precision essential for optimal energy transfer during your swing. This rubber-centric manufacturing represents a dramatic evolution from the featherie era, when craftsmen spent up to 8 hours stuffing wet goose feathers into leather pouches by hand.

Once that core clears inspection, it's time to build the layers that actually separate a $15 ball from a $50 one. You'll hear manufacturers brag about "four-piece construction" or "five-piece technology," but here's what that actually means for your game.

Each mantle layer gets molded around the previous one using compression or injection techniques. Workers control temperature and pressure with surgical precision because sloppy adhesion ruins everything. The process requires multiple passes to nail the right thickness and uniformity. Half shells made from thermoplastic urethane or ionomer are stored on heat-resistant trays before being assembled with the rubber cores. Manufacturers use X-ray technology to verify proper alignment between the core and outer layers.

These layers aren't random. Synthetic rubber delivers resilience and flexibility. Thermoplastics offer durability and moldability. The magic happens when engineers combine different hardness levels across layers; that's how they dial in spin control, energy transfer, and feel. The mantle layer typically contains ionomer resins or proprietary material blends that fine-tune how the ball responds to different shots. Your swing speed determines which combination works best.

Before the cover goes on, your golf ball is basically a bouncy sphere with zero aerodynamic purpose; it would fly like a knuckleball and drop out of the sky 50 yards short of its potential.

Here's where engineering takes over. Manufacturers use compression or injection molding to wrap thermoplastic covers, typically ionomer or urethane, around your ball's core and mantle layers. The magic happens in precision-crafted steel molds featuring hundreds of dimple cavities. These molds press at up to 1,200 psi, simultaneously forming the cover and stamping those aerodynamic indentations in one shot.

Those dimples aren't decorative. They're computationally designed to reduce drag and enhance lift. The number, depth, and arrangement vary by design, but the molds guarantee every ball flies similarly. Immediate cooling locks everything in place. This precision matters because dimples reduce drag by 50% compared to smooth balls, making the difference between a respectable drive and an embarrassing dribbler.

Quality control at this stage is critical; companies like Titleist subject every mold cavity to 100% inspection to ensure each dimple pattern meets exact specifications before a single ball is produced. This level of uniform construction and performance consistency explains why premium balls like the TaylorMade TP5 show minimal variability, with spin rates varying less than 150 RPM between balls.

Your dimpled cover's now locked in place, but it looks like a dull, unfinished prototype, and that matte surface would scuff on the primary tee shot.

Here's where precision meets protection. Manufacturers initially polish and clean the cover, then hit it with corona discharge treatment to guarantee the paint actually bonds. Mechanized spray robots apply two or more urethane-based paint layers while balls spin on posts, thickness controlled to ten-thousandths of an inch so aerodynamics stay intact.

Once dry, pad printing stamps your logo with surgical precision. Then comes the critical clear topcoat: a thin protective layer cured under controlled heat or UV light. This coat delivers the glossy sheen, water repellency, and abrasion resistance that keep your ball performing round after round. For matte finish golf balls, manufacturers use silicon-based matting agents in the topcoat to create that distinctive low-gloss texture while maintaining durability. Modern production lines feature fully automated systems that handle feeding, dust removal, spraying, drying, and cooling in one seamless workflow, dramatically reducing labor costs while ensuring consistent quality across thousands of balls. At facilities like Callaway's Chicopee, Massachusetts plant, robotic automation and skilled workers combine to produce millions of premium golf balls daily with exacting precision.

Though a ball might emerge from the painting booth looking tournament-ready, it hasn't earned that status until it survives a gauntlet of inspections that'd make most manufacturing processes look lax.

You're looking at multi-stage verification that starts with raw material screening, rubber compounds, urethane covers, and everything gets tested for elasticity, hardness, and chemical stability before it touches an assembly line. Defective materials don't get second chances.

During assembly, mechanized machinery maintains tight tolerances while technicians catch flaws before they're baked into the final product. Every ball faces dimensional testing against USGA and R&A standards: weight, size, symmetry, compression, and initial velocity. These compression ratings are particularly critical since proper compression maximizes distance and must match specific swing speed requirements for optimal performance.

Visual inspection uses AQL sampling to catch paint defects, dimple errors, and surface blemishes. Even microscopic imperfections affect aerodynamics, so balls outside tolerance get rejected, no exceptions.

You'll get about 7 rounds, roughly 126 holes, before your ball's performance noticeably drops off. That's the real-world number, not the marketing spin. If you're storing unused balls properly, they'll hold up for around 10 years, though I've seen degradation creep in after 7. Watch for scuffs, scratches, or dimple damage; those are your signals to swap it out, not when you lose it in the rough.

Yes, top-grade recycled balls perform nearly similarly to new ones. I've seen the data: driver tests show recycled AAAAA balls land within 1-2 yards of brand-new models, with ball speed and statistically indistinguishable spin rates. You're paying half the price for the same performance. The catch? Stick with reputable suppliers and avoid "refurbished" balls; repainting can mask flaws and alter weight.

Professional golfers prefer certain brands because consistency matters more than marketing promises. You'll find 71% of top pros use Titleist because the Pro V1 delivers predictable spin control and feel shot after shot. It's not brand loyalty, it's trust built through thousands of tournament rounds. Pros choose balls that eliminate variables, and when your paycheck depends on performance, you don't gamble on unproven equipment.

Yes, weather conditions absolutely affect golf ball manufacturing, though you'd never know it from the finished product. Factories obsessively control temperature and humidity because even slight deviations wreak havoc. High humidity causes rubber to absorb moisture, creating inconsistent cores. Extreme cold makes compounds brittle. Excessive heat accelerates curing unpredictably. That's why manufacturers invest heavily in climate-controlled facilities; they're compensating for nature's chaos so you don't have to.

You've just seen the extraordinary engineering that goes into every golf ball you tee up. From the precisely mixed rubber core to those aerodynamic dimples, each step exists to enhance your performance. Understanding this process helps you appreciate why ball selection matters and why not every ball suits every swing. Next time you're choosing, you'll know exactly what you're paying for beneath that glossy cover.